We understand our customers’ changing needs and requirements and provide them a wide range of steel products and services as well as fast, flexible and as just-in-time deliveries in a total cost-effective way. Our understanding of customer needs together with our delivery performance and competence in products and applications support the development of our customers’ business and create them competitive edge in the global competition

- Cut to lenght

- Packaging and labelling

- Additional markings accoring to agreement

- Tailor made packaking according to agreement

- Heat management and tracking, material certificates on request

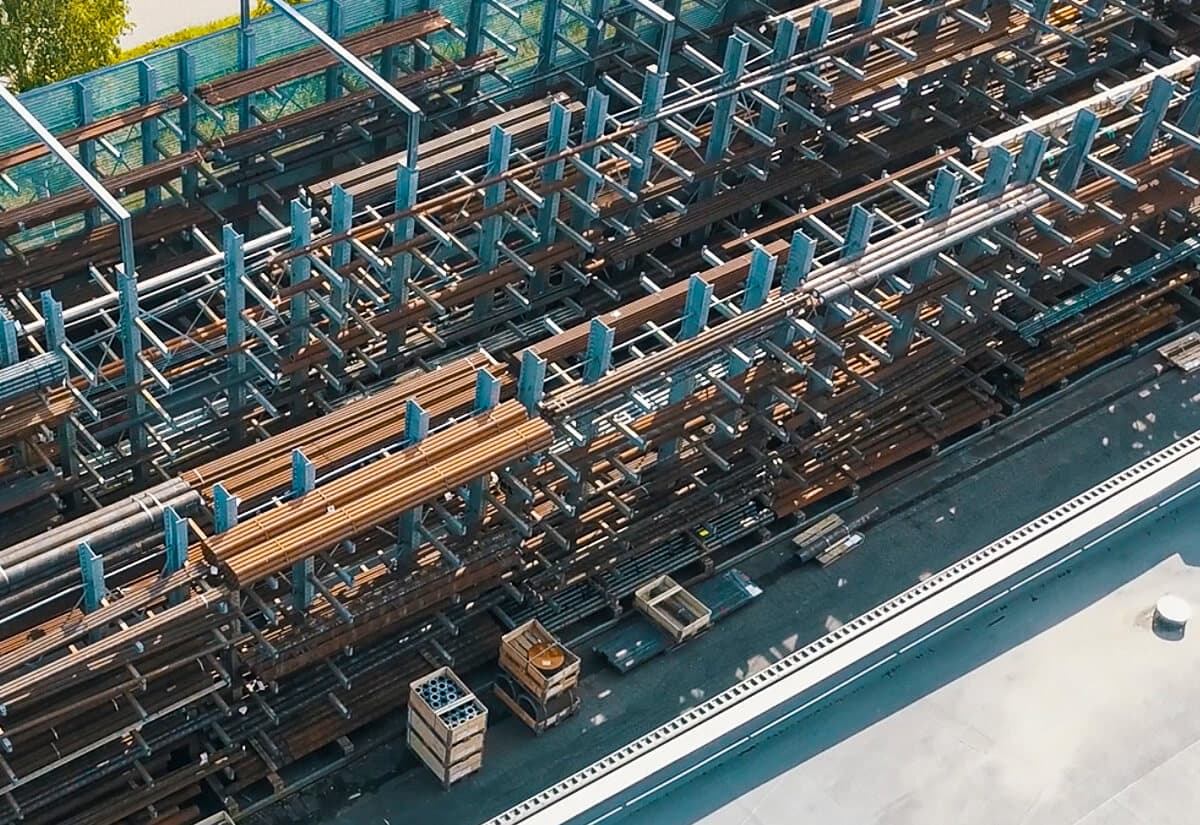

- Warehousing / logistical services

Cooperation with our main logistic partners enables direct deliveries and competitive prices.